Page 185 - TS1_5.4

P. 185

3 842 528 596 (2018-02) TS 1 5.4 Bosch Rexroth AG 13–1

Index · Index · Index

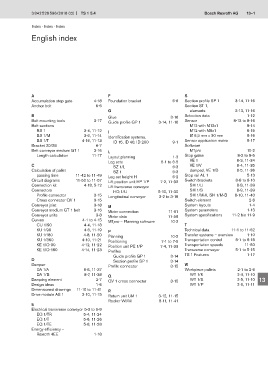

English index

A F S

Accumulation stop gate 4-18 Foundation bracket 6-6 Section profile SP 1 3-14, 11-16 1

Anchor bolt 6-6 Section ST 1,

G elements 3-13, 11-16

B Glue 3-16 Selection data 1-12 2

Belt mounting tools 3-17 Guide profile GP 1 3-14, 11-16 Sensor 8-13 to 8-16

Belt sections M12 with M12x1 8-14

BS 1 3-4, 11-12 I M12 with M8x1 8-15 3

BS 1/M 3-6, 11-14 Identification systems, Ø 6,5 mm x 30 mm 8-16

BS 1/T 4-16, 11-13 ID 15, ID 40, ID 200 9-1 Sensor application matrix 8-17

Bracket 20/28 6-7 Software 4

Belt conveyor medium GT 1 3-16 L MTpro 10-2

Length calculation 11-17 Layout planning 1-3 Stop gates 8-2 to 8-5

Leg sets 6-1 to 6-5 VE 1 8-3, 11-34 5

C SZ 1/L 6-3 VE 1/V 8-4, 11-35

Calculation of pallet SZ 1 6-3 damped, VE 1/D 8-5, 11-36

passing time 11-42 to 11-49 Leg set height H 6-2 Stop rail AL 1 5-13 6

Circuit diagrams 11-50 to 11-57 Lift position unit HP 1/P 7-2, 11-32 Switch brackets 8-8 to 8-10

Connection kit 4-18, 5-12 Lift transverse conveyor SH 1/U 8-8, 11-39

Connectors HQ 1/U 5-10, 11-30 SH 1/S 8-9, 11-39 7

Profile connector 3-15 Longitudinal conveyor 3-2 to 3-18 SH 1/M-A, SH 1/M-B 8-10, 11-40

Cross connector QV 1 3-15 Switch element 2-8

Conveyor joint 3-18 M System layouts 1-4 8

Conveyor medium GT 1 belt 3-16 Motor connection 11-61 System parameters 1-13

Conveyor units 3-8 Motor data 11-58 System specifications 11-2 bis 11-9

Curves 4-1 to 4-15 MTpro – Planning software 10-2 9

CU 1/90 4-4, 11-18 T

KU 1/90 4-6, 11-19 P Technical data 11-1 to 11-62

KU 1/180 4-8, 11-20 Planning 10-2 Transfer systems – overview 1-10 10

KU 1/360 4-10, 11-21 Positioning 7-1 to 7-5 Transportation control 8-1 to 8-18

KE 1/O-90 4-12, 11-22 Position unit PE 1/P 7-4, 11-33 Transportation speeds 11-60

KE 1/O-180 4-14, 11-23 Profiles Transverse conveyor 5-1 to 5-15 11

Guide profile GP 1 3-14 TS 1 Features 1-17

D Section profile SP 1 3-14

Damper Profile connector 3-15 W 12

DA 1/A 8-6, 11-37 Workpiece pallets 2-1 to 2-6

DA 1/B 8-7, 11-38 Q WT 1/K 2-4, 11-10

Damping element 2-7 QV 1 cross connector 3-15 WT 1/S 2-5, 11-10 13

Design ideas 1-6 WT 1/P 2-6, 11-11

Dimensioned drawings 11-10 to 11-41 R

Drive module AS 1 3-10, 11-15 Return unit UM 1 3-12, 11-15 14

Rocker WI/M 8-11, 11-41

E

Electrical transverse conveyor 5-3 to 5-9 15

EQ 1/TR 5-4, 11-24

EQ 1/T 5-6, 11-26

EQ 1/TE 5-8, 11-28 16

Energy efficiency –

Rexroth 4EE 1-18

17